Description

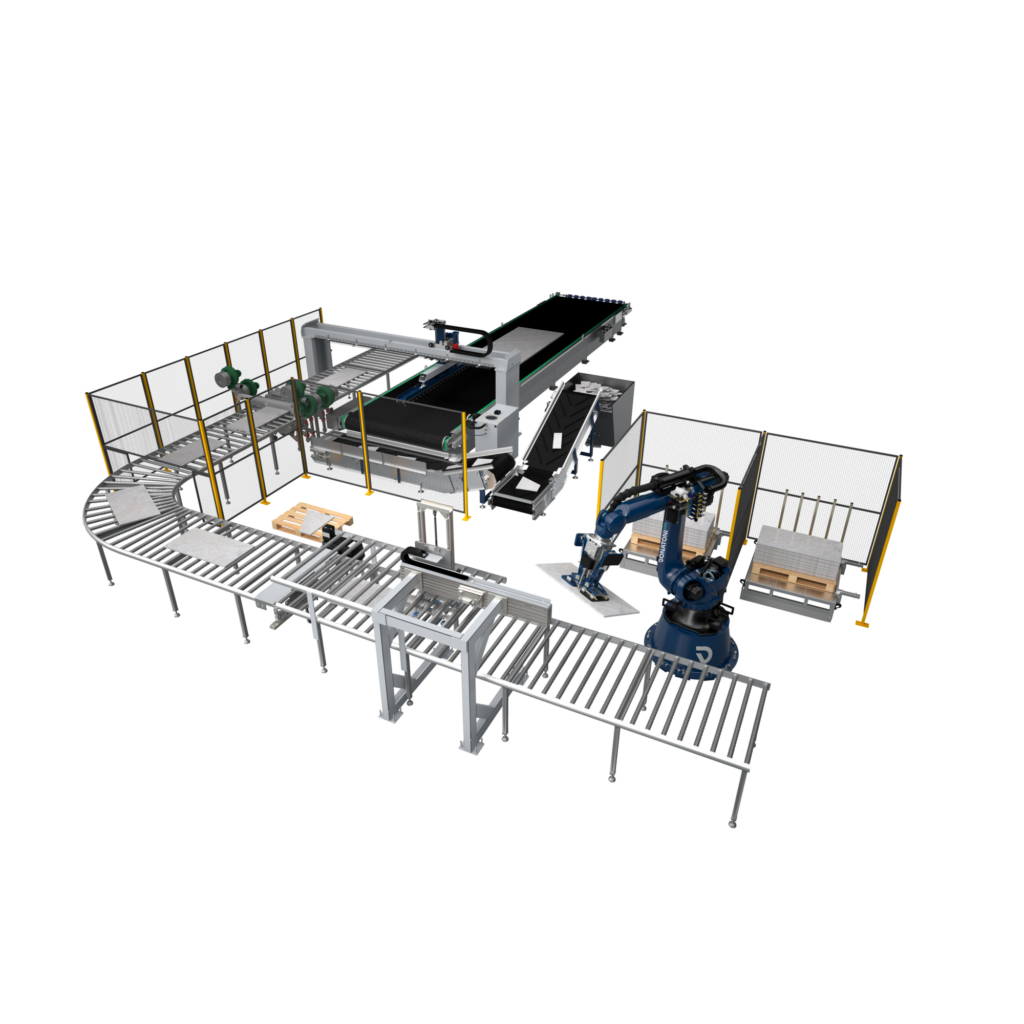

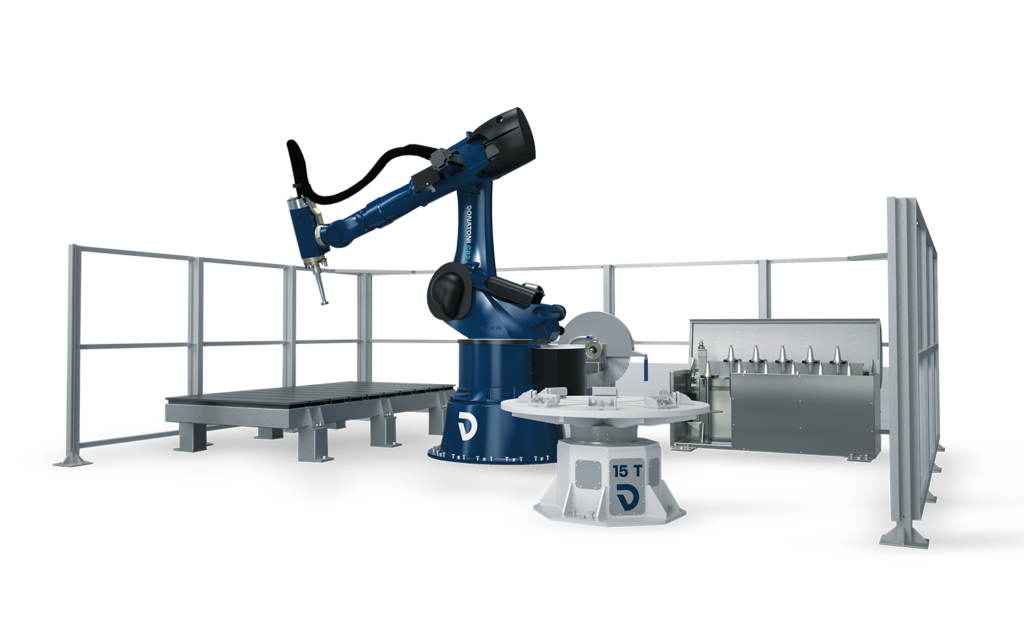

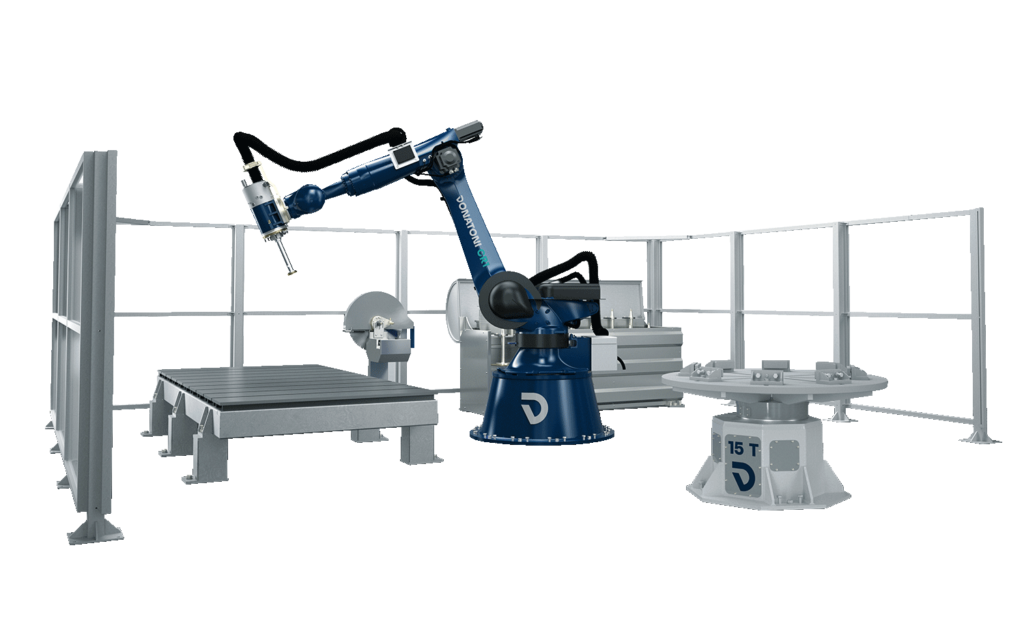

GEKO is an automatic loader designed for the automation of marble and granite processing lines. GEKO loads the slabs directly from the storage and places them on the motorized roller conveyor that feeds the processing line, allowing the “Book Match” processing too. GEKO is operated by a CNC system and the motion is generated by brushless motors.

The suction cups panel is able to perform rotations over 180 degrees. GEKO is equipped with a motorized roller conveyor. This machine adopts some particular mechanical solutions, such as linear guides and 49 anodized aluminum suction cups divided into 5 groups, and can be programmed with the integrated touch screen through a simple interface. All these features position GEKO amongst the best automatic slab loaders in terms of speed, precision, and safety, also suitable for handling particularly fragile and fractured slabs.

Optional: a rotating slab holder platform to allow slab load/unload even when the machine is working.