Digital Suite

An eco-system of software

and digital platforms

Over the years we have developed an infrastructure of software and platforms that can interact with one another and give you even more support with production process automation and digitalization.

Our intention is to harmonise the different digital tools implemented over the years and to make the daily work of those who work with and on our machines easier and more cost-effective. We believe that innovation can lead our sector towards a new working dimension, keeping industry and craftsmanship together.

Digital Suite

Easystone

Scan CNC

Zenitlux

Cyberface

Project Match

D-Krossfix

D-portal

EasyJET

D-Mes

Easy Match

Isocam

Parametrix

A dedicated software house for your machines

Donatoni has a whole department that specialises in the development of custom software to help you control and plan the machining processes of your machines. A key integration for business.

The “brain” in our machines

The development of proprietary software helps us offer continuous implementations, efficiency, constant improvements, and active listening.

The team strength

A young and dynamic team of ITC and other engineers who are sensitive to your every need working with you, because you will have an active role in the development process.

Over 23,000 hours

of software development every year

A team of 12

specialised technicians

Over 400 machines

examined

Advantages

Donatoni systems are more efficient because the software we create is specifically designed for our machines.

We provide you with intuitive and efficient tools to address all the challenges and complexities of our industry.

Donatoni software follows the evolution of your business and the entire industry, so it is always up-to-date, monitored and efficient.

Contacting support initiates a process, through an integrated system, that involves all the resources needed to respond quickly and efficiently.

The fact that our software is tailored means that it comes from an active listening phase and extensive sharing of the need.

Software ownership allows us to find answers quickly and provide the required implementation as soon as possible.

What do we do?

01 Analysis, design and development

We offer anything needed for the preliminary phase of work: from the study of each detail to final installation.

02 New features

Updates, changes, and implementations in line with the latest market and industry innovations

03 Support and assistance

Meeting demands primarily means being available and efficient, as well as providing quick technical support.

Example. PARAMETRIX.

Parametrix is not just a software solution, it is the Donatoni’s software solution.

This is not merely software: this is our gem. The result of an over 10-year long work, it is a key tool for machines to perform all 2D cutting, drilling, and milling processes. It is intuitive, user-friendly and recognised by all our customers and more generally by our industry as an innovative tool.

ZENITLUX

Programming software designed for the Zenit polishing/calibrating machine. Developed by Donatoni, it can be used to polish, calibrate, smooth and brush slabs of marble, granite and stone in general. It is the ideal software for processing the most delicate surfaces such as mosaics and onyx inlays or semi-precious stones.

PARAMETRIX

Parametrix is the simple, intuitive software developed by Donatoni and created to optimise the cutting of pieces with different shapes from the slabs. You can manage blade cutting operations and insert straight and curvilinear shapes(stairs, kitchen tops, rectangles, covers) using forms that are pre-set or which have been imported from a DXF file.

ISOCAM

DONATONI ISOCAM allows files to be created for the execution of straight or concave and convex arc shapes, with vertical and horizontal blades. With Isocam, shaping can be done in the roughing (combing) and the finishing (brushing) modes, but also in the combined mode.

EASY MATCH

Easy Match is a specific programming software developed by Donatoni for the realisation of simple open-book projects. It is an extension of the Parametrix software and gives a preview of the final result.

PROJECT MATCH

Project Match is a design software developed by Donatoni that allows complex “matching vein” or “open-book projects” to be realised on several slabs simultaneously. It is a highly professional tool, ideal for all companies realising contract projects for designers and architects, where a high aesthetic component is required.

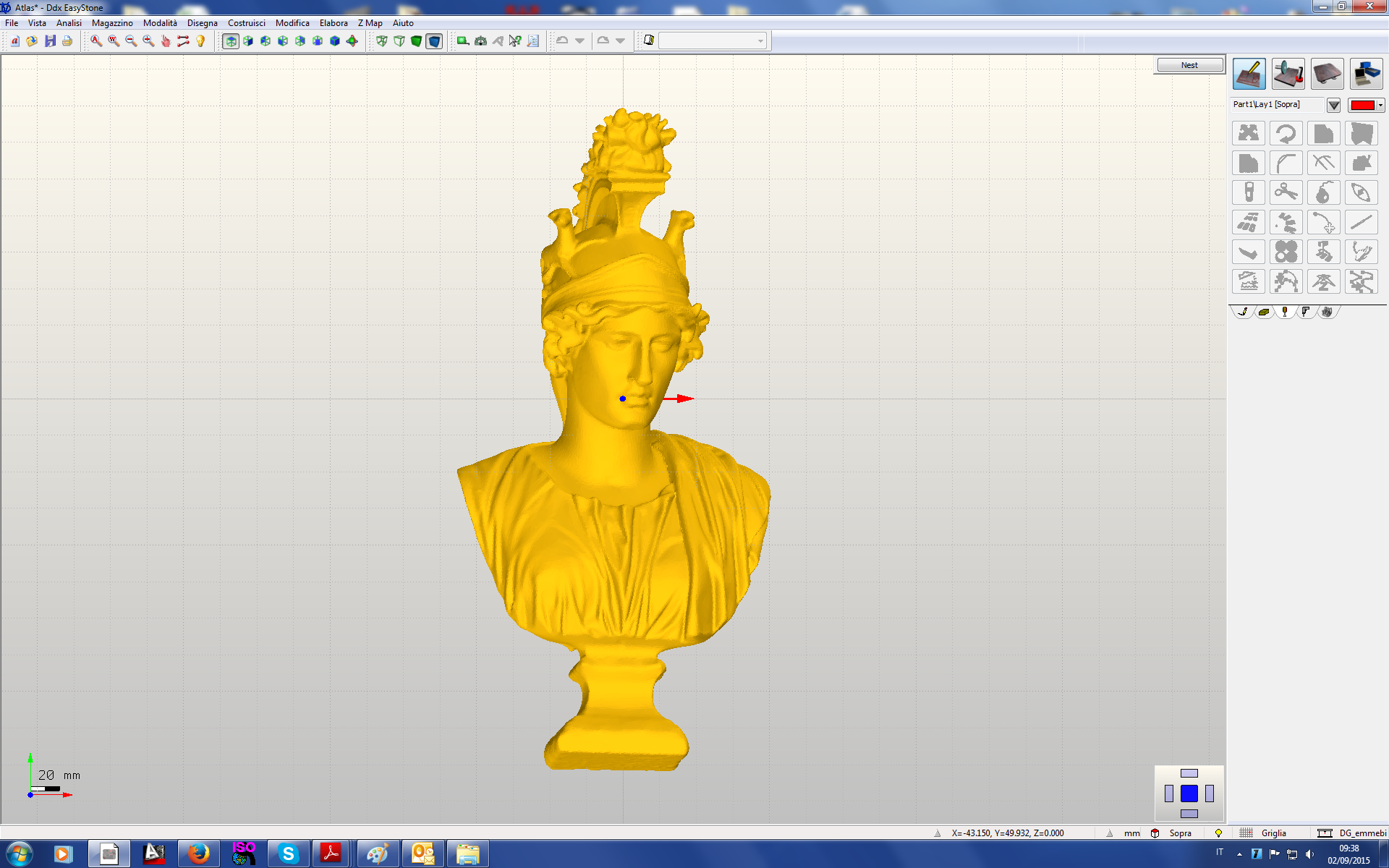

CYBERFACE

Cyberface is the CNC software interface specially designed and developed for Donatoni CR01/02 robots. This innovative tool allows complex sculpting and shaping operations to be performed with impeccable precision and quality, so that customers can exploit the full potential of robots.

EASYSTONE

Easystone is the CAD/CAM software specific for the marble processing sector. It is a simple, intuitive software program: all the functions are “click-friendly” and can be used even by people with no specific computer skills.

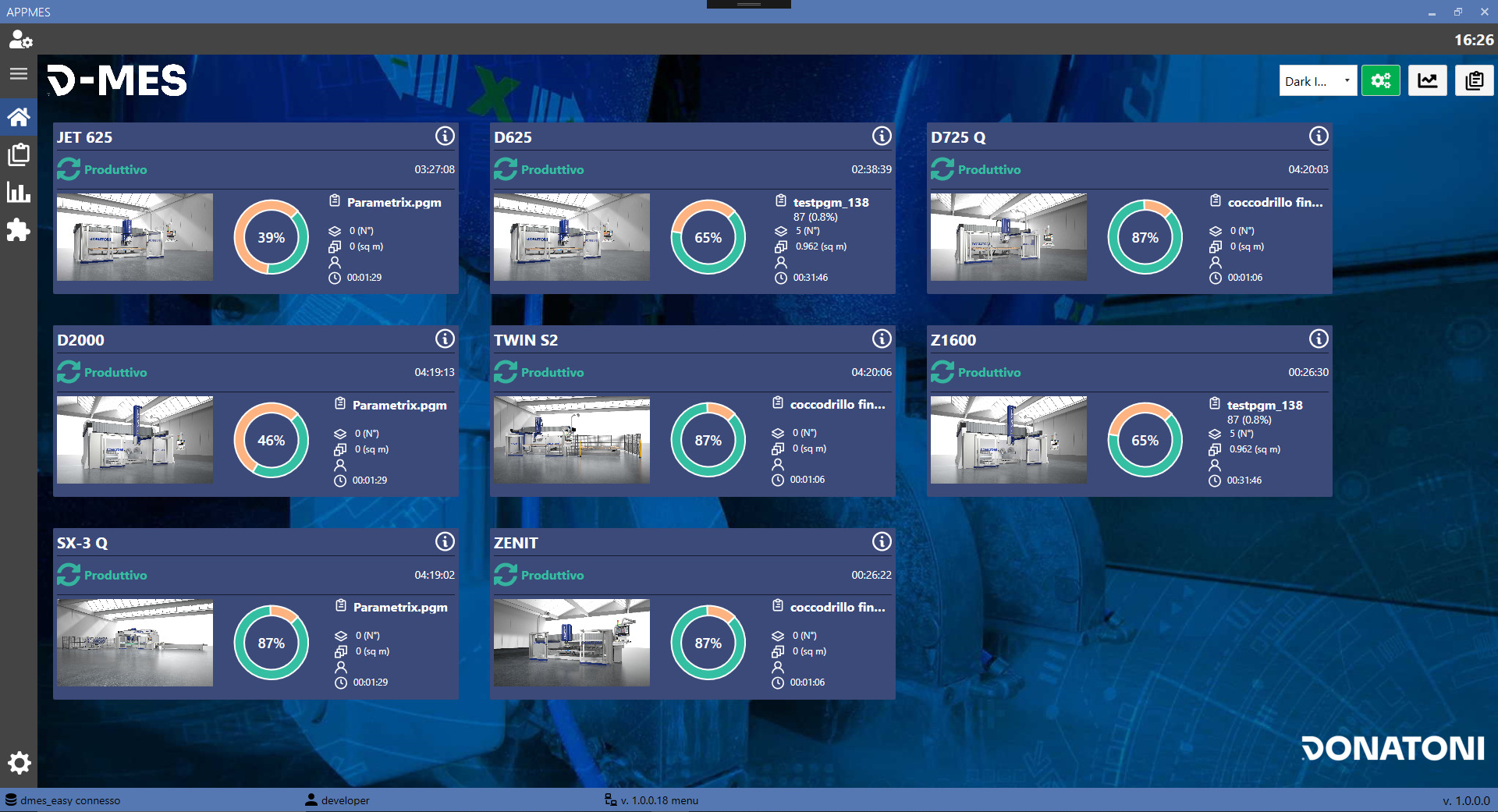

D-MES

DONATONI MES is the first MES system on the market designed and manufactured exclusively for the stone industry. It is not just a software: it is a complete MES (Manufacturing Execution System) system that can support your company’s growth.

D-KROSSFIX

The Krossfix software was implemented for Donatoni KROSS. It is used to optimise management of machining processes performed on all four sides and on the top surface of each workpiece; it is intended to control cutting, drilling, and milling operations. The setup capabilities of the software help programme the operations rapidly and in a user-friendly manner.

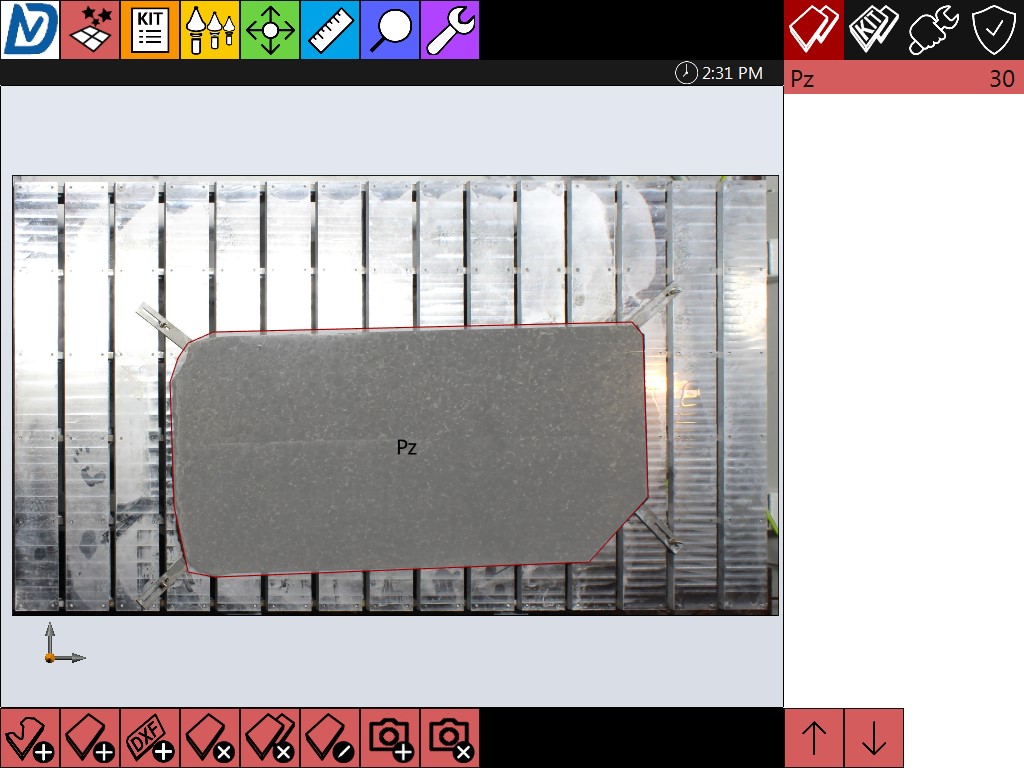

SCAN CNC

Detection system made up of a laser pointer mounted on the machine head and a software program integrated with Parametrix that identifies two-dimensional shapes. When detection has ended, the operator elaborates the shape on the machine display with Parametrix, and can archive the file, either in the on-board machine computer or in an external device.

EASYJET

EasyJET is a software specifically designed for Waterjet machine operations. Thanks to its extensive options and features, the software allows for maximum optimization of all aspects related to waterjet CNC machining.

D-PORTAL

The D-Portal platform can be considered as a library for all your Donatoni machine documents and has direct channels for contacting our After Sales service directly, which means that clients can do ordinary maintenance easily and precisely.

D-PLANT

D-PLANT is the software specifically designed for the comprehensive management and supervision of unloading and palletizing lines. Its close integration with unloading robots and its visual and intuitive approach significantly simplify the user experience.